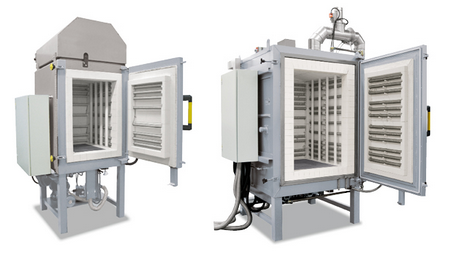

Combi Chamber Furnaces up to 1400 °C for Debindi ng and Sintering in one Process FURNA PECKA ZA VISOKA TEMPERATURA

N 200/DB - N 1000/14DB

The combi chamber furnaces N 200/DB - N 1000/14DB are specially developed for debinding and sintering in one process. The furnaces have a fresh air supply providing for dilution of the exhaust gases produced during debinding, for safe prevention of an inflammable atmosphere in the furnace chamber. The standard version of the furnaces includes debinding package I, with fresh air injected at room temperature in the furnace and with a factory pre-set volume flow with respect to the organic volume to be vaporized. In addition, the furnaces have an exhaust gas fan that is also factory pre-set and provides for a safe underpressure in the furnace. This system prevents exhaust gases from escaping into the production area. The passive safety package immediately intervenes when the underpressure in the furnace chamber drops. This system is recommended for reproducible processes in which the load does not change.

If the furnace is to be used flexibly with changing loads, we recommend debinding package II. The furnace then includes fresh air preheating with variable fan speed and injection of the warm fresh air through air distribution tubes. The exhaust gas fan also operates at variable speed. The PLC control system automatically adjusts the underpressure in the furnace chamber.

- Tmax 1280 °C, 1340 °C or 1400 °C

- Five-sided heating from all four sides and from the floor for a good temperature uniformity

- Heating elements mounted on support tubes provide for free radiation and long service life of the heating wire

- Bottom heating protected by SiC tiles on the table to provide a level stacking surface

- Multi-layer insulation consisting of lightweight refractory bricks backed by special insulation

- Self-supporting and long-life ceiling construction, with bricks laid in arched construction

- Motor-driven exhaust air flap on the furnace roof

- Debinding package I with passive safety package and monitoring of the underpressure in the furnace chamber, exhaust gas fan, fresh air fan, preset underpressure in the furnace chamber, controlled by Nabertherm controller P 300

- Over-temperature limiter with manual reset for thermal protection class 2 in accordance with EN 60519-2 as temperature limiter to protect the furnace and load

Additional equipment

- Multi-zone control adapted to the particular furnace model for optimizing the temperature uniformity

- Commissioning of the furnace with test firing and temperature uniformity measurement (also with load) for the purpose of process optimization

- Debinding package II with passive safety concept

- Exhaust air and exhaust gas tubing

- Thermal or catalytic exhaust cleaning systems

- Process documentation and control with Controltherm MV software package, NTLog and NTGraph for the basic furnace or Nabertherm Control Center (NCC) for monitoring, documentation and control