Search

Categories

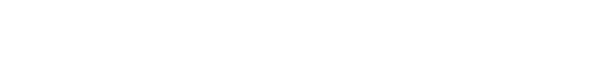

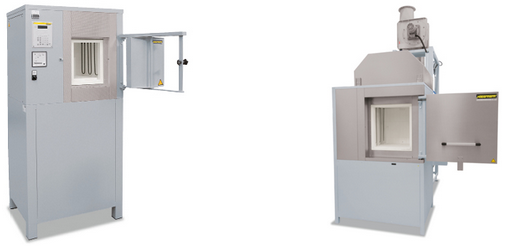

High-Temperature Chamber Furnaces with Molybdenum Disilicide Heating Elements with Fiber Insulation up to 1800 °C FURNA PECKA ZA VISOKA TEMPERATURA

HT 04/16 - HT 450/18

The high-temperature chamber furnaces HT 04/16 - HT 450/18 have proven reliable over many years in the lab and in the production of technical ceramics. Whether for bioceramics, for sintering CIM components or for other processes up to a maximum temperature of 1800 °C, these furnaces afford the optimal solution for the sintering process.

High-temperature chamber furnaces can either be insulated with fiber material or lightweight refractory bricks. Furnaces with fiber insulation achieve significantly shorter heating up times because of the low thermal mass. An insulation made of lightweight refractory bricks (see HFL models on page 35), on the other hand, has the advantage of better chemical stability.

These furnaces can also be tailored to specific processes by means of a wide range of additional equipment. The addition of a debinding package, for example, allows the use of these models as combi furnaces for debinding and sintering in one process. Thermal or catalytic exhaust cleaning equipment round up the system.

- Tmax 1600 °C, 1750 °C or 1800 °C

- Dual shell housing with fan cooling for low shell temperatures

- Heating from both sides via molybdenum disilicide heating elements

- High-quality fiber insulation backed by special insulation

- Side insulation constructed with tongue and groove blocks provides for low heat loss to the outside

- Long-life roof insulation with special suspension

- Chain-guided parallel swivel door for defined opening and closing of the door

- Labyrinth sealing ensures the least possible temperature loss in the door area

- Specially reinforced furnace floor for accommodating high charge weights for model HT 40 and above

- Exhaust air opening in the furnace roof

- Heating elements switched via SCR‘s

- Over-temperature limiter with manual reset for thermal protection class 2 in accordance with EN 60519-2 as temperature limiter to protect the furnace and load

Additional equipment

- Uncontrolled or controlled cooling system with frequency-controlled cooling fan and motor-driven exhaust air flap

- Commissioning of the furnace with test firing and temperature uniformity measurement (also with load) for the purpose of process optimization

- Temperature measurement with thermocouples, types B and type S with automatic pull-out device for precise control results in the low temperature range

- Protection grid in front of the heating elements to prevent mechanical damages

- Special heating elements for zirconia sintering provide for longer service life with respect to chemical interaction between charge and heating elements

- Protective gas connection for purging the furnace with non-flammable protective or reaction gases

- Manual or automatic gas supply system

- Gas supply system in the furnace chamber with ceramic bell jar, protective gas inlet and outlet from below for better sealing when operating with protective gases and/or to prevent from chemical interactions between the load and the insulation or the heating elements

- Parallel swivel door opening upwards, also motor driven

- Bottom insulation made of durable lightweight refractory bricks for heavy charge weights

- Motorized exhaust air flap, switchable via the program

- Debinding package I with passive safety package and monitoring of the underpressure in the furnace chamber, exhaust gas fan, fresh air fan, preset underpressure in the furnace chamber, controlled by Nabertherm controller P 300

- Debinding package II with safety concept

- Exhaust air and exhaust gas piping

- Thermal or catalytic exhaust cleaning systems

- Process documentation, display and control via HiproSystems control system

Reviews

Contact

SHOP

= EUROLUKS.MK =

E-mail: electrolux@t-home.mk

E-mail: natasa@electrolux.mk

Telephone-Bitola: +389 (0) 47 203 330

Telephone-Skopje: +389 02 3298 130

Fax: +389 (0) 47 203 900

Mobile Phone Number: +389 (0) 70 237 108